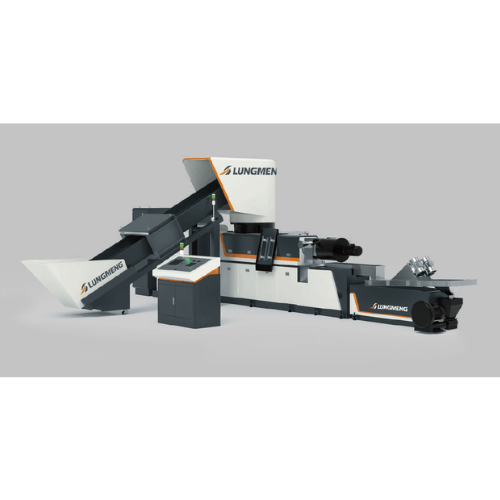

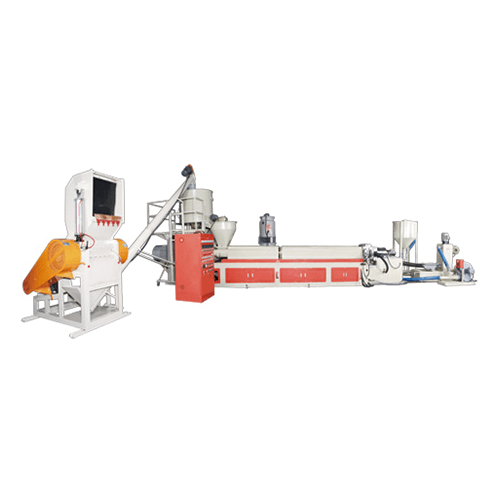

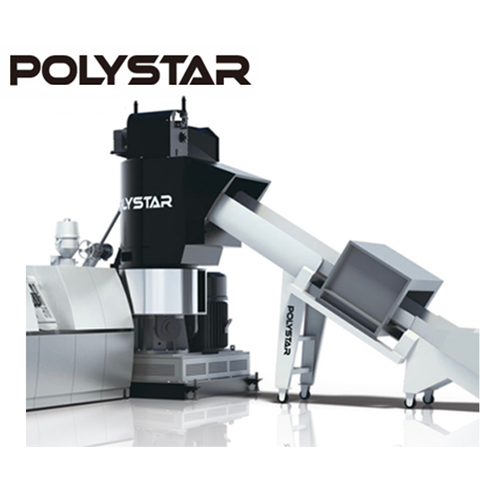

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Waste Recycling Machines

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

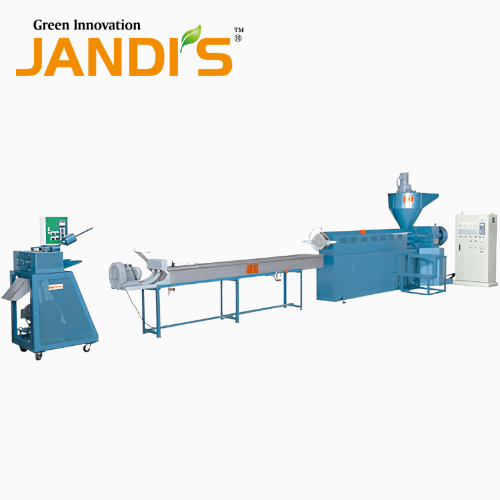

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. With two holes screen, increase capacity by non-stop prodcution while screen changing. Two stages filter makes material more clean High capacity in lump shape, recycled bottle and masterbatch materials.

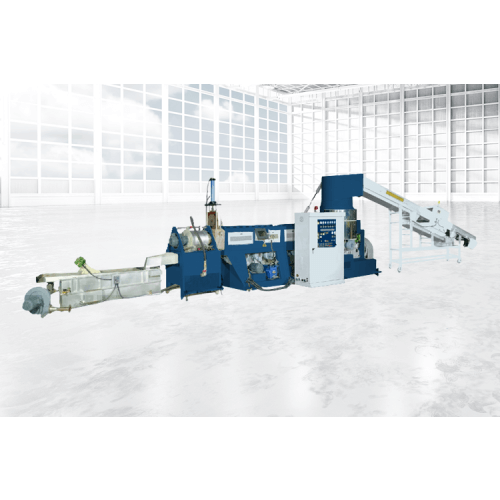

Plastic Recycling Machine - Gator Series

Categories : Plastic Waste Recycling Machines

Applicable materials : HDPE , LDPE and PP. Designed for high material process stability and production. Vent design on the barrel evaporates the volatiles from the recycled material. Hydraulic screen change unit and pressure gauge for easy operation and safety. Water chamber with die face cutter simplifies the process. Easy operation, low downtime and quick maintenance.

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Plastic Pelletizer Machines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost save up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

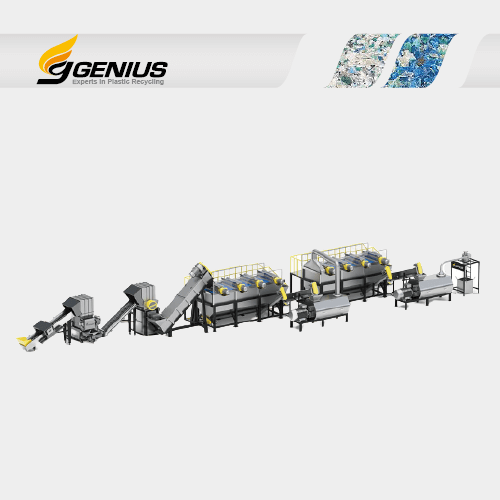

Plastic Rigid Washing Plant

Categories : Loaders and Conveyors

The rigid washing plants are designed for recycling post-consumer hard materials like bottles, injection waste, or rigid materials. These systems produce uniform plastic flakes with high purity and low moisture level.

PE Waste Plastic Recycling Making Machine

Categories : Plastic Waste Recycling Machines

DIE-FACE CUTTING MODEL(PE)

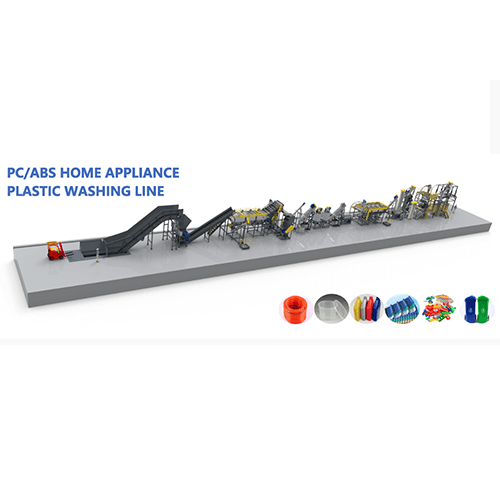

Rigid Plastics Recycling System

Categories : Plastic Waste Recycling Machines

Rigid Plastics Recycling System

Hopper Feeding Recycling Machine: Repro-Direct

Categories : Plastic Waste Recycling Machines

● The Perfect Solution for recycling plastic films waste/ regrind/ granules ● Crusher and conveyor can be added and combined into a complete recycling line

Shredder Integrated Recycling Machine

Categories : Plastic Shredders

Can handle large heavy materials or thin-film materials, such as lump from screen changer, roll material, bulk barrel, containers..., Two-stages filtration makes raw materials cleaner, fully automatic, and reduces the labor operating time. Operate easily. Accept customize., One machine with multiple functions.Solving complicated production, and the adjustment process is fast-High productivity, low noise, Easy operation, Blades removal is easy and reusable

FILM/BAGS WASTE PLASTIC RECYCLING MACHINE : KCR-150

Categories : Plastic Waste Recycling Machines

Each blown film machine is equipped with an electronic length counter and an accumulated time meter. In addition, all main output shafts are precision ground for exceptional stability and quiet operation.

Rigid Plastics and PE Film Recycling System

Categories : Plastic Washing Line

Rigid Plastics and PE Film Recycling System

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Categories : Plastic Waste Recycling Machines

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Plastic Recycling Machinery and Equipment

The equipment is specially designed for reproducing wastage from PP/HDPE woven bags. BOPP, film.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

PET Bottle Recycling Washing System

Categories : Plastic Washing Line

PET Bottle Recycling Washing System

3-in-1 Plastic Recycling and Pelletizing Machine

Categories : Plastic Pelletizer Machines

The machine consists conveyor, shredding drum, extruder and pelletizer to integrate the production to minimize working time and save the manpower.

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force feeding. Able to open a input hole on top of barrel to conduct feeding formula and master batch pellets. It's a useful and productive type. Crusher is optional. With forced feeding hopper allows the machine to input two kind of material.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

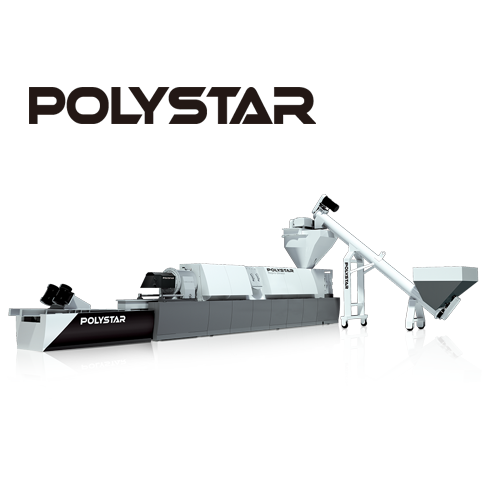

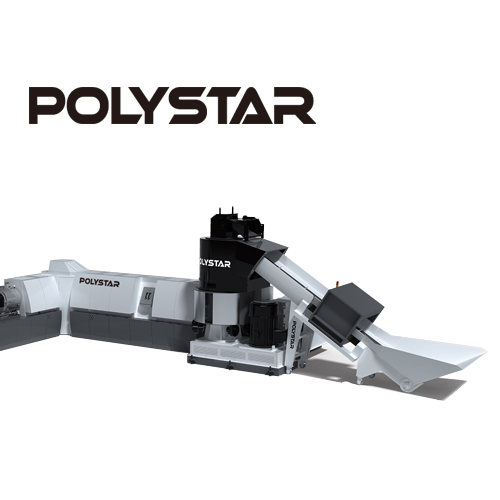

Two Stage Recycling Machine: Repro-FlexPlus

Categories : Plastic Waste Recycling Machines

Two Stage Recycling Machine with integrated cutter compactor. Improved degassing and filtration.

EPS Pastic Waste Recycling Machine

Categories : Plastic Waste Recycling Machines

EPS PLASTIC WASTE RECYCLING MACHINE

Recycling Machine - Film, Raffia, Regrind (PE/PP): Repro-Flex

Categories : Plastic Waste Recycling Machines

● High efficiency recycling line for post-industrial packaging film ● With cutter compactor integrated which eliminates the need to pre-cut material

Crusher and Storage Plastic Waste Recycling Machine

Categories : Plastic Crushers

Crusher and Storage Plastic Waste Recycling Machine

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Plastic Pelletizer Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. More Labor-saving The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS